Many people ask us about the durability of strings and recommended replacement intervals. This isn't an easy question to answer because many factors determine ageing and wear. The action of putting strings under tension has little ageing effect. The most significant factors are mechanical wear, contamination and corrosion and these very much depend on how the string is handled and played.

The typical contaminants in the fingerboard area are perspiration, salt, fatty acids and all kinds of dirt, dust and dead skin. In fact it is the same type of pollution that you'll find on your computer keyboard after using it for several months.

Some players hope that they can prolong a string's lifespan with regular cleaning. However, cleaning the entire string length to try to prevent contamination and corrosion is much less effective than one would assume.

A string's construction is quite complex and it gets affected by penetration of all kinds of pollution during its life time. The construction of wound strings cannot be sealed. The winding has to be open in order to allow the string vibrate freely. Once the string becomes contaminated, you unfortunately can't wash the dirt out. (Regular removal of rosin build up in order to maintain good response is recommended of course. You can read how to do it properly here.)

Contaminants.

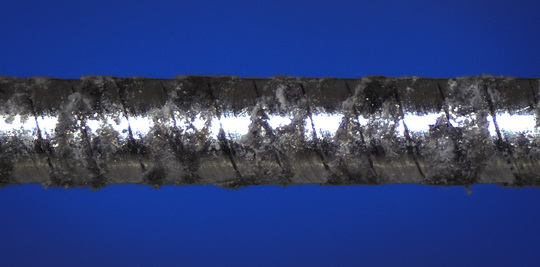

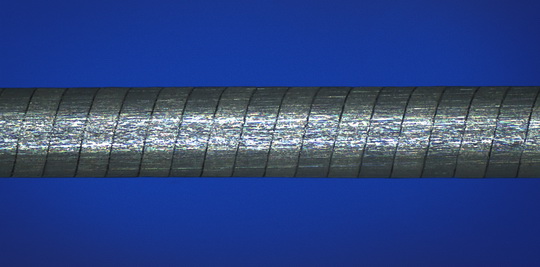

Dirt can damp the string even from outside. If it gets inside it affects the tone even more. If you wash your hands before every playing session you won't experience this with your strings. (This string has been turned slightly from its original position. The dirt doesn't deposit on the top of the string.)

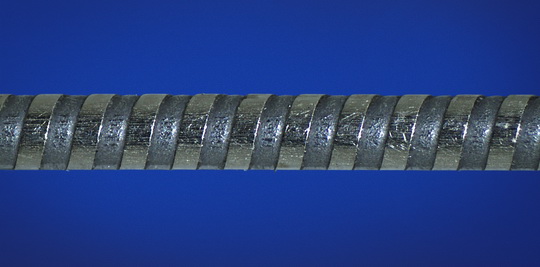

The outer winding has been removed from a used string. Most of the dirt and debris sits just under the outer winding if it's not pushed inside by a liquid.

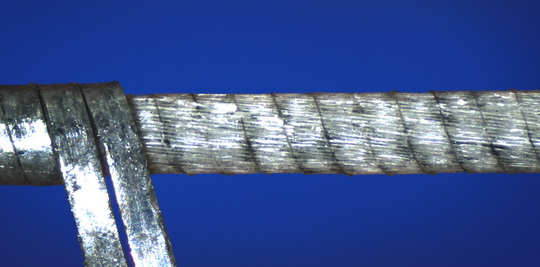

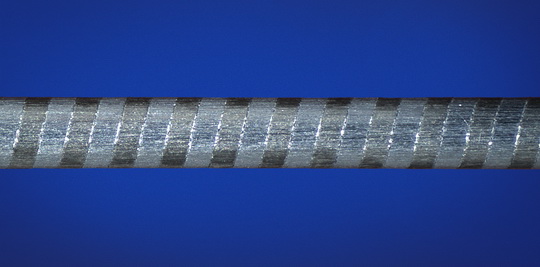

A string with a contaminated core. If your hands sweat a lot then the whole string construction is affected. If not, the amount of pollution reaching the centre of the string isn't as high. However, using any liquid cleaner will only push the pollution deeper and deeper inside. It can never be washed out of the string.

Corrosion.

Some people have a problem with intensive aluminium corrosion. Hydronalium is a little more resistant to corrosion, but the difference is not significant. Silver and stainless steel however do not cause such problems.

There is a huge difference in corrosiveness between people. Some players can play all types of strings including aluminium strings for years. On the other hand, there are violinists who completely destroy any aluminium wound ‘A’ string in as little as three weeks. According to some scientific research, as well as our experience, the corrosiveness is supposed to be determined by the player's diet but genetics also seem to be involved.

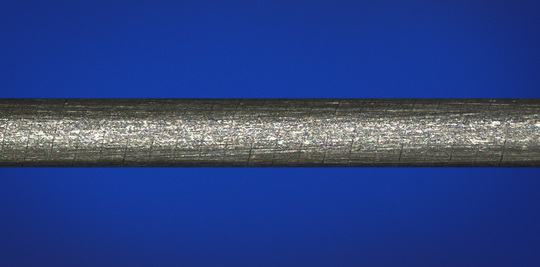

This is a new string. You can see the polished surface structure.

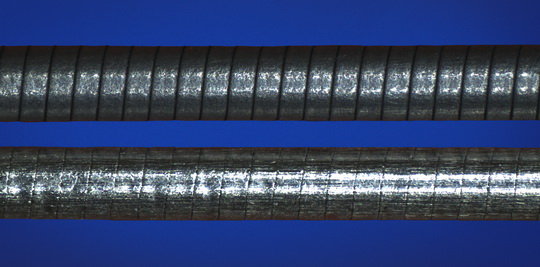

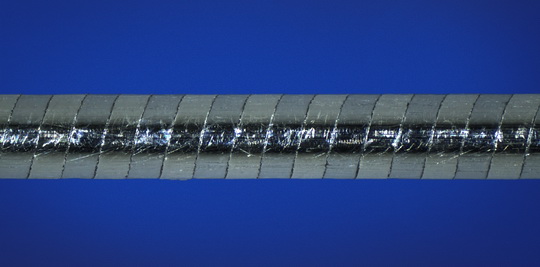

Slight aluminium corrosion. You can compare the condition of the aluminium string (on the top) with the silver one of the same age and wear. The aluminium starts to look like roughly shaped rock.

Heavy aluminium corrosion. This string was sent to us by mistake. It was made by another reputable string manufacturer. Aluminium corrosion is a common problem which affects all major brands. Despite intensive research and development we haven't been able to resolve it yet either. This is why we offer strings in alternative materials which are mentioned later in this article.

You can see the aluminium corrosion clearly on our Vintage and Amber D strings. They have a unique winding construction which comprises of wound aluminium next to silver on the top. It makes the corrosion issue even more visible. However we keep this formula because it offers the ultimate sound results for violin D strings.

A new Brilliant Vintage violin D string. You can see the very slight colour shade difference of the two metals. Aluminium is grey, silver looks a little more golden.

Slight aluminium corrosion on the same string.

Heavy aluminium corrosion of Vintage D string. You can see disintegrated aluminium on the bottom while there is dirt on the top. The best way to prevent a short string life is to wash your hands regularly before playing.

This Vintage D has been played quite heavily for four months by another person. In the top picture you can see the upper fingerboard section (close to the bowing area). The silver has become tarnished due to humidity in the atmosphere. The aluminium remains intact.

In the bottom picture there is an intensively played fingerboard area of the same string. Both metals have been polished from daily use. The original polishing traces have been replaced by accidental wear marks. None of the metals have been affected by corrosion. The player is a vegetarian who limits their intake of sugar and particularly salt.

There is also other scientific research that indicates that diet does influence metal corrosiveness. However we do not want you to change your diet, we have designed an appropriate string for almost everyone.

If you suffer from aluminium wound strings having a short lifespan there is little chance of relying on string cleaning. We definitely recommend washing your hands before each practice session to everyone. If that doesn't help, we recommend avoiding aluminium and hydronalium in string formulas. From our product range the only strings that might be affected are violin and viola A and D strings.

We make all viola A strings in a metal (stainless steel) alternative too. For violinists, we have developed the Russian Style A and Avantgarde A strings. They have a warm timbre, despite their metal core construction, together with exceptional durability. For D strings, violin players may prefer to choose silver alternatives in our Karneol, Brilliant and Amber lines.

There is no aluminium in the upper winding of our cello strings.